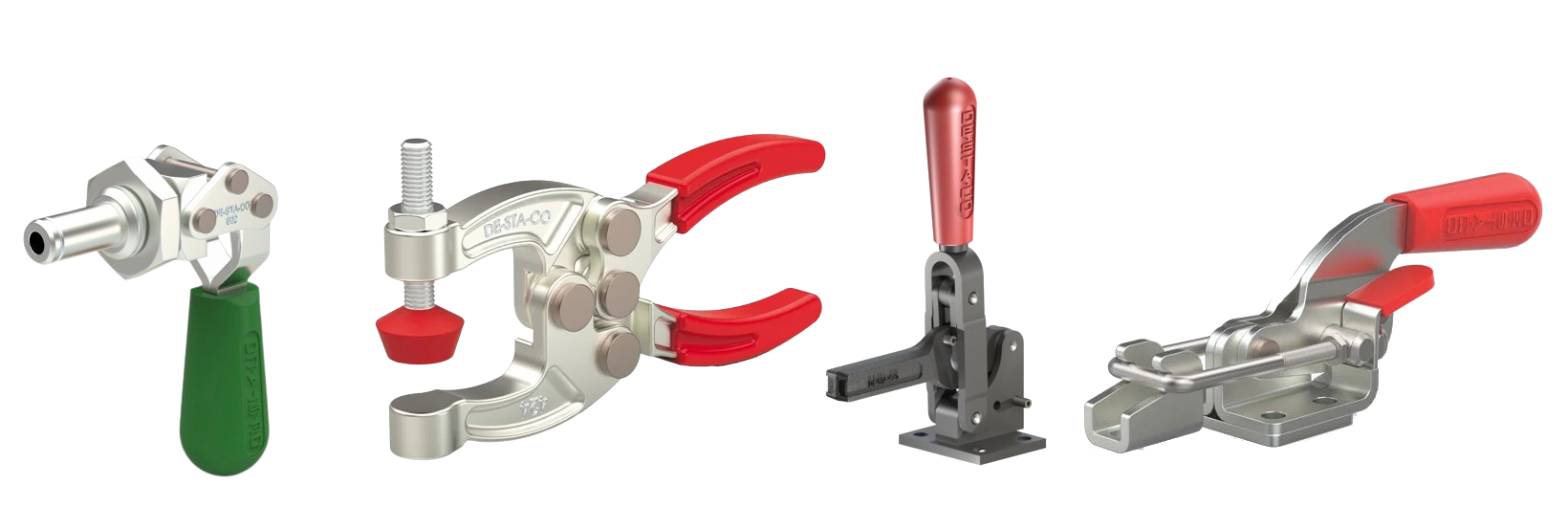

Manual Clamping Solutions to hold a workpiece securely

DESTACO has become a global leader in the design and manufacture of high-performance automation, workholding, and remote-handling solutions, consistently delivering innovative products that enhance productivity and efficiency for manufacturers across industries such as automotive, life sciences, aerospace, consumer packaged goods, and nuclear sectors. As the authorized distributor of DESTACO products in India, BIBUS INDIA ensures that these industry-leading solutions are readily available to Indian manufacturers, helping them achieve optimal performance and maintain a competitive edge.

Manual Clamping Solutions: Manual clamping is a fundamental aspect of workholding that involves securing a workpiece in place manually during manufacturing processes such as welding, assembly, or machining. The primary function of a manual clamp is to hold objects securely to ensure precision, safety, and efficiency in various operations. Since 1936, when the first manual toggle clamp was introduced, this technology has set the standard for workholding solutions.

- Vertical Hold Down Clamps: These clamps apply downward force to hold a workpiece securely on a flat surface. They are ideal for applications requiring quick and repeatable clamping action.

- Horizontal Hold Down Clamps: Similar to vertical clamps but with a horizontal handle, these clamps are used when overhead space is limited or when a horizontal application is needed.

- Straight Line Action Clamps: These clamps move a plunger in a straight line to engage and hold a workpiece. They are commonly used in applications requiring a strong, straight-line holding force.

- Pull Action Latch Clamps: These clamps are designed to pull two components together, such as the lid of a container and its base. They are perfect for applications where two parts need to be securely latched together.

- Squeeze Action Clamps: These clamps operate with a squeeze handle, allowing the user to apply force quickly and easily. They are often used in applications where a quick-release mechanism is beneficial.

To meet specific customer needs, company provides three levels of customization for its manual clamping products:

- Simple Alterations: Minor modifications to standard products, such as changing the handle orientation or altering the clamp size, to better fit the customer's application.

- Complex Custom Products: For more intricate requirements, we can design and manufacture completely new clamping solutions from scratch, tailored to meet the precise needs of the customer.

- Color Handles for Manual Clamps: We offers manual clamps with handles in five different colors, which can be used for visible assignment to security levels, operating modes, or maintenance intervals. This customization is particularly valuable for customers who need to implement standardized color codes for safety or organizational purposes.

- Stainless Steel Clamping Solutions: For applications that demand robust, corrosion-resistant, and heat-resistant clamps, we offers a line of stainless steel clamps. These clamps are ideal for industries such as food processing, chemical handling, pharmaceutical manufacturing, and outdoor environments where traditional steel clamps may not withstand the harsh conditions.

Industries and Applications for Manual Clamping Solutions

- Automotive: Clamps are used in assembly lines for welding and fixture holding.

- Aerospace: Precision and reliability are critical in holding components during assembly and testing.

- Food and Packaging: Stainless steel clamps are preferred for hygienic and corrosive environments.

- Pharmaceutical: Clamps are essential in securing components during manufacturing and packaging processes.

- Industrial and Manufacturing: Clamps are widely used in general manufacturing, machining, and assembly operations.

- Consumer Packaged Goods: Clamps play a crucial role in ensuring consistency and precision in packaging processes.