Vision Sensor CS-60: The Future of Industrial Quality Inspection

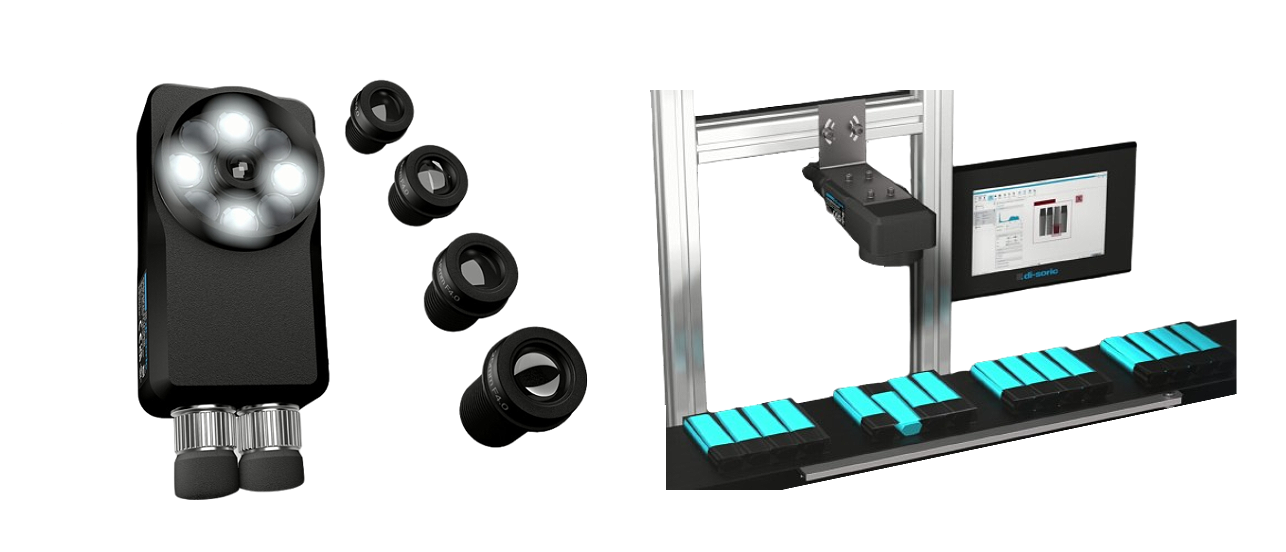

The CS-60 Vision Sensor is designed for flexible and automated quality inspection in industrial processes, helping to ensure that products meet defined standards before further processing. It features easily interchangeable M12 lenses, integrated red and white high-power LED illumination, and robust image processing tools. The user-friendly nVision-i software allows for simple setup and seamless integration.

Key features include:

- Comprehensive Lens Options: M12 lenses cover a wide range of focal lengths.

- High-Power LED Illumination: Switchable in software for optimal startup in various conditions.

- Upgradeable Software: Modules for measurement and ID reading can be added.

- Industrial Protocol Support: Compatible with TCP/IP, ProfiNet, Ethernet/IP, and more.

- Durable Design: IP67-rated housing for tough environments.

The CS-60 Vision Sensor excels in various quality inspection tasks, playing a pivotal role in ensuring product quality and process efficiency. Here are some common applications:

Quality Inspection of Components

Before a product is packaged, it must be inspected to verify its quality. The CS-60’s flexibility in terms of working distance and field of view, coupled with its powerful LED illumination, makes it an ideal choice for inspecting different product characteristics. It helps manufacturers detect defects early, ensuring only compliant products move on to the next phase.

Completeness Inspection and Position Tracking for Parts Handling

At various stages of production, the CS-60 can be used to check for completeness and the correct positioning of components. For example, in robotics applications, the sensor can verify that all necessary parts are present and correctly positioned before the robotic arm picks them up. This minimizes errors and ensures smooth automation.

Traceability and Code Reading

The CS-60's advanced ID reading tools can decode all common 1D and 2D barcode types, including challenging DPM (Direct Part Marking) codes. This makes it invaluable for track-and-trace applications, where products must be identified and traced throughout the manufacturing and distribution process.

The CS-60 Vision Sensor represents a significant advancement in industrial automation, offering the following benefits:

- Reduced Inspection Time: Automating the inspection process speeds up production while maintaining a high standard of quality.

- Minimized Errors: With the CS-60's reliable inspection capabilities, manufacturers can catch defects early and reduce the likelihood of faulty products reaching customers.

- Scalability: The sensor's modular software upgrades allow for easy expansion of its capabilities as needs evolve.

- Ease of Integration: With support for multiple protocols, the CS-60 can be quickly incorporated into various industrial setups.

The CS-60 Vision Sensor is more than just a tool for quality inspection – it’s a strategic investment in the future of your production process. Its combination of flexible hardware, upgradeable software, and robust build quality ensures that it can keep up with the ever-changing demands of modern manufacturing.