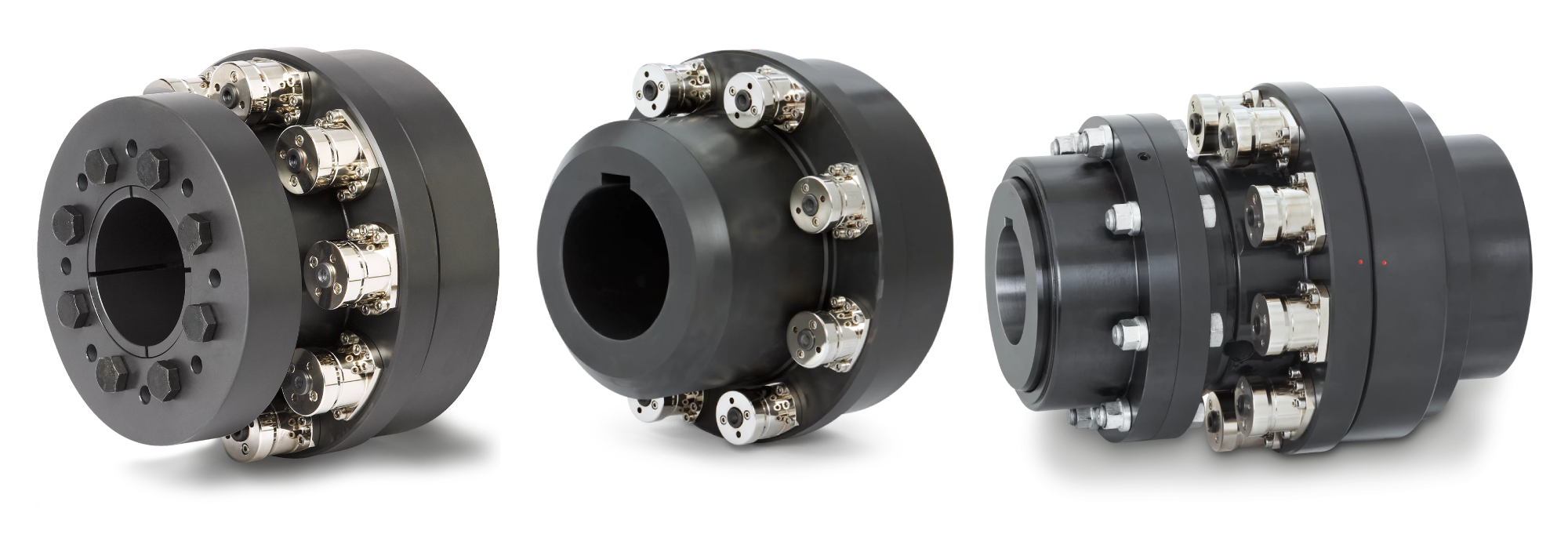

Safety couplings

Industrial couplings are crucial for transmitting large torques, requiring robust and reliable designs. These couplings often feature flexible elements to efficiently compensate for shaft misalignment, ensuring optimal performance and longevity. R+W couplings stand out for their flexibility and extensive customization options. With a wide range of designs and connection options, provides tailored coupling solutions. Additionally, their large portfolio of standard coupling models meets diverse product needs, making R+W a versatile choice for various applications.

Key Advantages of Safety Couplings

- Compact and robust design: Ideal for space-constrained applications.

- Full disengagement: Protects machinery by completely separating components during overload.

- Exact torque limitation: Ensures precise control of torque transmission.

- Adjustable disengagement torque: Allows customization based on specific application needs.

- ST Series Safety Couplings: Advanced Overload Protection. The ST series safety couplings are engineered to decouple machine drives during torque overloads, preventing damage and reducing downtime. Key features include:

- Ball bearings and detents: Spring-loaded ball bearings are mounted on plungers, which retract into housings during overload, ensuring complete separation.

- High clutching forces: Achieved with a compact profile due to individually loaded plungers.

- Adjustable torque: The transmittable torque is determined by the number, force setting, and position of safety elements.

- Reinforced Bearings for High Performance: All safety coupling variants feature reinforced bearings designed for high speeds and the absorption of axial and transverse loads. Depending on the application, these may include angular contact or tapered roller bearings.

- Detent receptacle: Holds the safety elements in place.

- Adjustable plunger mechanism: Allows for customization of the disengagement force.

- Re-engagement Mechanism: After an overload condition, the safety elements do not re-engage automatically. An axial force is required to reset the safety elements into the detents of the output plate.

In summary, safety couplings provide reliable protection and enhance system availability by minimizing downtime and damage during overload conditions. With customizable torque settings and robust designs, they are essential for maintaining the efficiency and longevity of industrial machinery.